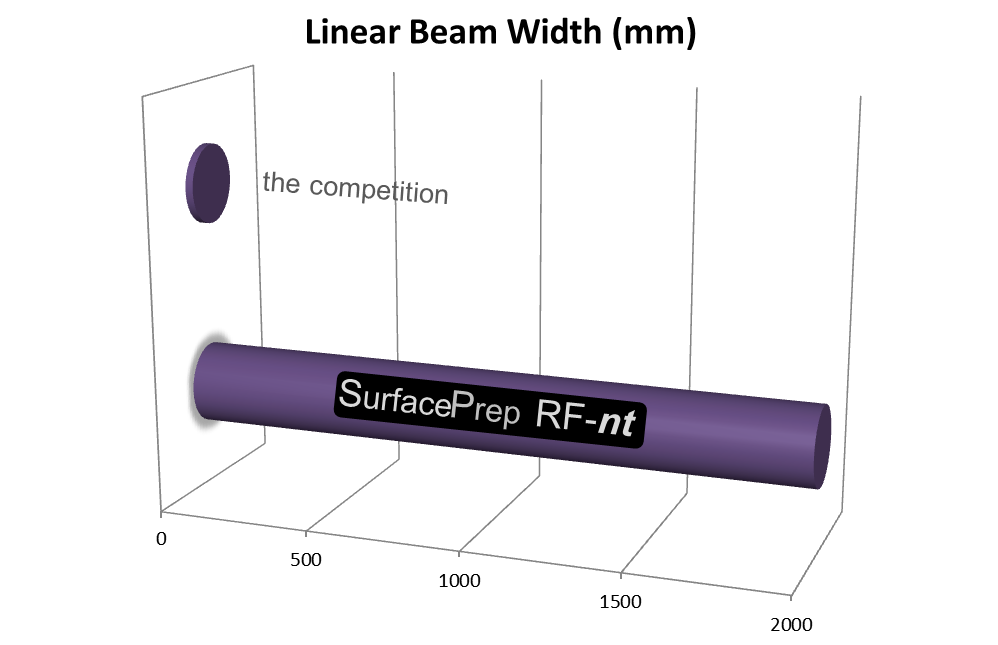

Intrface Technologies specializes in non-contact surface preparation solutions using atmospheric pressure plasma treatment systems. We offer the widest range of atmospheric plasma treatment technologies available. Treat both 2D and 3D surfaces and plasma treat areas from 6mm all the way up to 2 meter wide with our linear plasma beams.

We offer several different types of atmospheric plasma technologies including both nonthermal RF capacitive discharge direct glow plasma and thermal torches. All of our plasma technologies are reliable, safe for both the operator and the surface being plasma treated, and highly efficient.

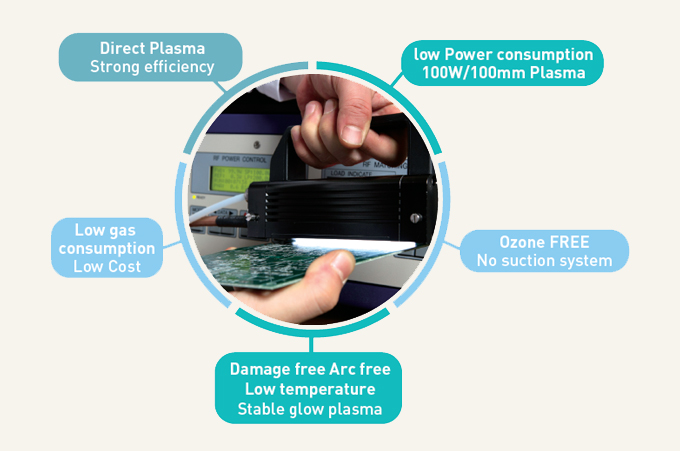

The SurfacePrep RF model line utilizes nonthermal RF capacitive direct glow discharge technology to offer the widest possible treatment area in an ultra clean and low temperature treatment environment.

The SurfacePrep XD atmospheric plasma treatment system is thermal plasma offering a cost effective solutions for R&D, process development and full production applications. The atmospheric plasma torch technology is now also available in a fully integrated and automated system.

Safe, clean, cost effective solution for non-contact surface activation & cleaning prior to bonding, coating & printing

True multi gas capability ensures low cost of ownership and simple facility installation.

Use your facility compressed air. Our systems do not require special CDA (Clean Dry Air) no special filtering required. This same atmospheric pressure plasma torch technology can easily run other process gases such as O2, N2, Ar or CO2 providing the flexibility to create the exact reactive species and chemical atmospheric plasma treatment needed to achieve your desired surface modification needs:

SurfacePrep atmospheric plasma systems treat both conductive and non-conductive materials. Low gas temperature atmospheric pressure plasma is safe on sensitive polymers, thin films and glass. Plasma treat stainless steel, Ti, NiTi, Au and other metals as well as these polymers

- Pebax

- PEEK

- Nylons

- Polyimide

- Silicone

- HDPE / LDPE

- PET

- PVC

- Polypropylene

- Silicone

- PDMS

Plasma treat any form factor from 2D flat surfaces to complex 3D MEMS and microfluidics. Typical applications include guide wire coating, catheter bonding & coating, electronics encapsulation, lab on chip, biotech – any Advanced Material Interface challenge.

Free your process from dangerous wet chemistry or dirty abrasive surface preparation methods. Try our safe, high speed atmospheric plasma solutions today.

Up to 400mm X and Y travel and 1000mm / sec max speed – the Surface Prep XD-iP Integrated Plasma system combines precise treatment dosage with full interlock safety features and carbon activated exhaust filtration.

The integrated atmospheric pressure plasma system is driven by a fully programmable touch screen UI with multiple access levels for R&D, process development and production applications.

Please see our data sheets and specifications below.

Click the links to download a PDF data sheet:

SurfacePrep XD atmospheric plasma system -

Intrface Technologies SurfacePrep XD Product Data Sheet - low res

SurfacePrep XD-iP fully integrated plasma system -

Intrface Technologies SurfacePrep XD-IP Product Data Sheet

Safe, clean, cost effective solution for non-contact surface activation & cleaning prior to bonding, coating & printing

Download SurfacePrep RF-nt data sheet here

Nonthermal RF Capacitive Discharge atmospheric plasma solutions. Our new ultra clean and high efficiency RF Direct Glow Capacitive Discharge (DgCd) plasmas are available with beam widths ranging from 6mm to 2000mm and can run on argon or helium. Traditionally, only available running helium as the carrier gas, RF Capacitive Discharge plasmas have shown exceptional promise as a very low temperature, ultra clean and ultra dense plasma source. The limited and costly supply of helium as a natural scarce resource has been a show stopper for production implementations of RF Capacitive Discharge plasmas - until now. Intrface Technologies now offers RF "Direct Glow Capacitive Discharge (DgCd)" systems that run on either argon or helium as the carrier gas. Additionally, beam width in atmospheric plasmas have always been a limiting factor in treating larger surface areas. While others may offer a 25mm or 50mm wide linear beam widths, Intrface Technologies offers beam widths up to 2000mm wide. That's right. Beam widths up with 2 meters wide.

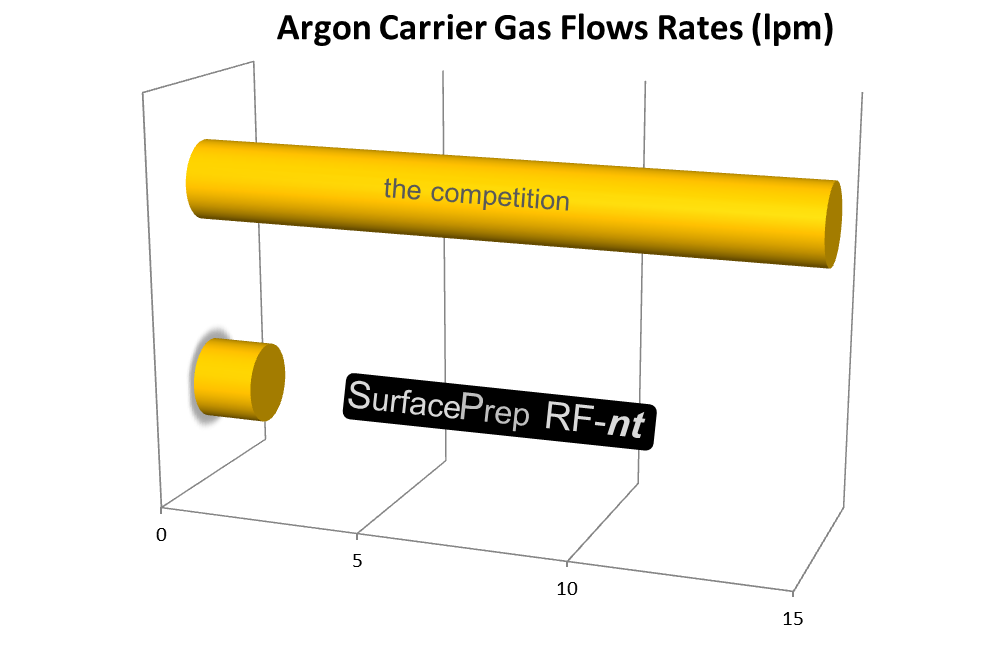

Our RF Capacitive Discharge atmospheric plasma technologies are also the most efficient on the market running at just a fraction of the process gas flow rates of other systems. That translates into significant cost savings in production and quicker ROI.

All of our plasma technologies are arc-free offering a safe operating environment for you and your device or materials. Treat objects with both conductive and non-conductive components without damage. We also offer portable systems for all of our technologies ensuring that we can bring the solutions to you and your facility to prove our your non-contact surface treatment process as quickly as possible using your real life post process.