Intrface Technologies atmospheric plasma Plasma Treatment for Printing and Label Application ensures the best possible high speed ink bonding and print quality.

Inkjet printing of product IDs, bar codes and other product identification applications on low surface energy materials can be problematic without a clean and high surface energy surface to adhere to. Intrface Technologies Blown Ion atmospheric plasma technology replaces traditional low density corona and potentially dangerous flame treatment systems. Backside (non-treated side) issues can also be eliminated used atmospheric plasma instead of corona. With plasma beam widths up for 100mm wide, our systems can handle most common label and font heights easily with one high speed system. As the pressure for higher output or line speeds increases, the need for a true high density yet safe air plasma solution is driving demand for our technology.

Most polymers and metals need an increase in surface energy to achieve a durable and high quality continuous ink jet (CIJ) print finish. Adhesion is the molecular force of attraction between unlike materials. The strength of attraction is determined by the surface energy of the material. The higher the surface energy, the greater the molecular attraction.

Extruded or molded polymers such as PVC, PEX, PET, vinyl, Nylon, Polyster, PMMA, PVA, Polystyrene, EVA, Polyethylene and Polypropylene all benefit from our atmospheric plasma non-contact surface cleaning and activation (high surface energy). Metalized surfaces, paper, foils and paperboard stocks can also be safely treated with atmospheric plasma. Reaching the proper surface energy level for proper ink adhesion is the key for quality high speed printing. Intrface atmospheric plasma systems offer the widest possible beam widths and highest power outputs ensuring lines speeds of up to 100 meters per minute.

Typical applications include PVC, PEX, Nylon pipe extrusion lines for the plumbing and oil & gas industry, coated wires, injection molded parts for cosmetic and pharmaceutical bottle printing and label application as well as large format high quality graphics utilizing UV printing technologies.

Critical printing applications include lot and part identification printing including part numbers, barcodes and 2D barcodes for the medical device, renewable energy and oil & gas industries. For regulatory purposes, proper identification must be maintained throughout the life of the part while exposed to harsh environmental conditions requiring long lasting quality printing results. I

Intrface Technologies solutions for atmospheric plasma treatment for printing and label application are the answer to your high speed, high quality and durable continuous inkjet and UV print challenges.

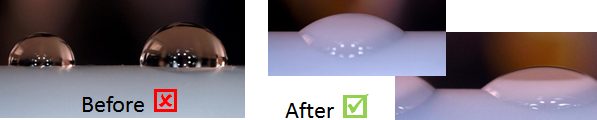

Check out this video in our application series pretreating PEX tubing on an extrusion line running at 170 feet per minute prior to continuous inkjet printing. Without plasma the ink comes completely off the part with test tape. After plasma treatment the ink is properly adhered to the PEX tubing