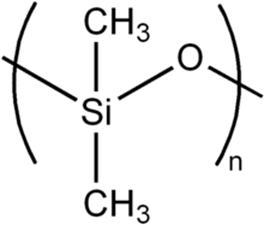

The following Intrface Technologies application note is on polydimethysiloxane (PDMS) bonding for Microfluidics and Other Non-Adhesive Bonding Applications with Atmospheric Plasma.

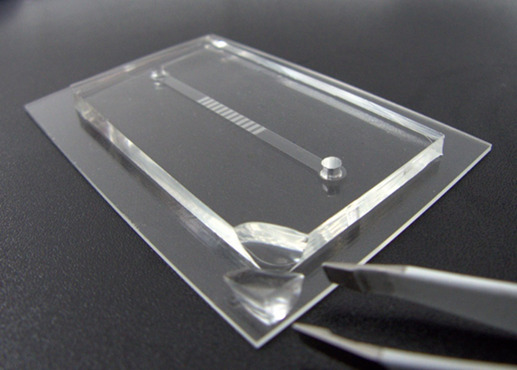

Atmospheric plasma is a low cost and high speed alternative to vacuum plasma systems for bonding PDMS to glass for microfluidics. You can Create a fast permanent bond between PDMS and glass using Intrface Technologies proprietary chemical atmospheric plasma system. PDMS (Polydimethylsiloxane) is a polymer typically used in the manufacture of microfluidics. Intrface Technologies has developed an atmospheric chemical plasma process to modify the surface of PDMS to enable permanent bonding to glass. Bond your microfluidic in seconds while simultaneously activating the microfluidic channels to improve speed & accuracy. You no longer need expensive vacuum plasma equipment with long cycle times for bonding PDMS. Bond your microfluidic in seconds with atmospheric plasma.

Atmospheric plasma technologies offer key advantages over vacuum plasmas such as:

- In-line processing

- Single part traceability

- Virtually form factor limitless

- Treat any size, length, shape, morphology

- No chamber contamination

- No chamber location variances

- No moving parts to wear out or maintain (vacuum pumps)

- High reactive species density

- Lower cost of entry and maintenance

Intrface Technologies is in a unique position to be able to offer several different types of atmospheric plasma technologies targeted to our expertise in solving cleaning, bonding, coating, functionalization and sterilization challenges. With over 50 years combined experience in the electronics, medical device, semiconductor, composites and bio tech arenas, we have the applications knowledge base to solve your cleaning, bonding, coating or sterilization challenges.

Related articles:

- S. M. Hong, S. H. Kim, J. H. Kim and H. I. Hwang., “Hydrophilic Surface Modification of PDMS Using Atmospheric RF Plasma”, Journal of Physics Conference Series 01/2006; 34. DOI: 10.1088/1742-6596/34/1/108. Abstract: Control of surface properties in microfluidics systems is an indispensable prerequisite for the success of bioanalytical applications. Poly(dimethylsiloxane) (PDMS) microfluidic devices are hampered from unwanted absorption of biomolecules and the lack of methods to control electroosmotic flow(EOF). Among the various methods of hydrophilic treatment, a new cleaner technology was chosen to treat PDMS. By using atmospheric RF plasma, hydrophilic surfaces can be created. Thus, analysis was conducted with AFM, XPS, and contact angle before and after plasma treatment. Constructing hydrophilic surfaces without changing the true character of that surface has previously been costly and time consuming. But by using atmospheric plasma cost and time are both greatly reduced. There are many other benefits of hydrophilic surface treatment, including the capability to increase adhesion and capillary effects, etc. Also, with hydrophilic treatment of the micro channels

on the PDMS surface, surface tension is reduced thus allowing fluids to move easily along those channels. However, the most important aim is to increase the capillary effects without any deposition or chemical treatment - Jongchan Choi, Kyeong-Hwan Lee and Sung Yang.,“Fabrication of PDMS through-holes using the MIMIC method and the surface treatment by atmospheric-pressure CH4/He RF plasma,” J. Micromech. Microeng. 21 097001. Abstract: This note presents a simple fabrication process for patterning micro through-holes in a PDMS layer by a combination of the micromolding in capillaries (MIMIC) method and the surface treatment by atmospheric-pressure CH4/He RF plasma. The fabrication process is confirmed by forming micro through-holes with various shapes including circle, C-shape, open microfluidic channel and hemisphere. All micro through-holes of various shapes in a wide range of diameters and heights are well fabricated by the proposed method. Also, a 3D micromixer containing a PDMS micro through-hole layer formed by the proposed method is built and its performance is tested as another practical demonstration of the proposed fabrication method. Therefore, we believe that the proposed fabrication process will build a PDMS micro through-hole layer in a simple and easy way and will contribute to developing highly efficient multi-layered microfluidic systems, which may require PDMS micro through-hole layers.

Contact us to find out more about bonding PDMS using atmospheric plasma or to receive a complimentary copy of the technical articles utilizing atmospheric plasma above. Please reference the authors and publication number in your email request (copy and paste into your email response).